#high pressure food processing pumps

Explore tagged Tumblr posts

Text

Fristam Centrifugal Pumps | Cast Iron Pump Manufacturer in India

#centrifugal pump manufacturers in india#industrial centrifugal pump manufacturers in india#high pressure food processing pumps

0 notes

Text

Hyper-Species Database Entry #001 | Gojira Serizawaii (“Godzilla”)

Species: Gojira serizawaii (Godzilla)

Title: The God of Destruction

First Modern Sighting: August 9, 1945

Temporal Range: 245-0 Ma

Height: 125.67 Metres

Weight: 132,053.47 Tonnes

Category: 0

The true apex predator of Earth’s entire global ecosystem, Gojira are a colossal species of highly derived semi-aquatic hyper-faunal synapsids from an era long-forgotten by humanity. Fossil evidence points towards a split from early gorgonopsid species in the Middle Permian of South Africa before reaching its current form in the Anisian stage of the Middle Triassic Epoch. Throughout the evolution process of the Godzilla species, its ancestors had somehow acquired G-cells and had subsequently begun to immigrate into radioactive deep-sea trenches. Over time this led to the development of large dorsal plates along the animals' spines. These leaf-like structures serve the function of absorbing sunlight and radiation from the surrounding area and converting it into “G-Radiation”, a specialized form of radiation that the species uses both to fuel itself and to power specialized abilities. The radiation can be carried throughout the body through large vein-like structures beneath the skin. This radiation is primarily stored in numerous small chambers along the back and the tail of the creature. Additionally, the plates form a crystal-like structure on the end of the creature’s tail that seems to also be capable of releasing excess radiation. Water from the gills is also filtered and used to cool the main reaction chamber. This system is referred to as the “nuclear system” and functions similarly to a nuclear reactor, creating energy with no need for food. Though the young need to eat quite often to supplement growth, it is common for the species to eat the remains of adversaries they have killed. In addition to gills, the animals also have lungs making them fully capable of surviving in any of Earth’s various environments. The lungs are connected to an additional sac used to store hydrogen for specialised defensive and offensive capabilities. The species also seems to be able to quickly adapt to new opponents as new structures form and change in short periods when faced with stress. This causes the species to be both highly unpredictable and it is likely why they’ve become so successful. Gojira even seems to be able to adapt to new forms of radiation and even DNA further modifying themselves beyond what any other known species is capable of. But these are not the only unique features of Godzilla’s body. To successfully pump blood throughout their entire body, the species has a total of three hearts, one is located in the chest, waist, and tail. This allows the species to keep a constant steady blood flow, though the veins are insanely durable as it is needed to balance the pressure from three hearts. Gojira also have a second, smaller brain located between their hips. This brain serves the purpose of controlling the movement of the tail and regulating cooling within the body.

Godzilla are believed to be among the most intelligent of all species on Earth, showing clear signs of both sentience and sapience. The species seems to be fairly expressive with their display of emotions, changes in posture, muscle tone, gait, facial expressions, vocalizations, pupil dilation, and even bioluminescence displays have been observed to occur. Evidence even points towards some level of understanding of other species as well as basic cross-species communication, though the species does seem to be somewhat antisocial and will not interact with others unless there is no other option. Gojira also seems to retain a high intellect with the ability to predict and interpret the actions of others, as well as showing an understanding of cause and effect and a relatively high level of problem-solving skills.

As with most kaiju, the scales of the Godzilla species are impenetrable to conventional weaponry, with typically only other kaiju or specially-made anti-kaiju weaponry able to do any damage to it. They are also resistant to nuclear weapons due to their atomic nature. Weapons made from the metal cadmium have been shown to at least serve as effective deterrents or methods of exhausting the daikaiju, though research is inconclusive as to the extent of this weakness and it varies between members of the species, especially if they had adapted due to a prior experience with the metal. In addition to the extreme defensive capabilities, Gojira also boast an intense regenerative ability, being able to recover from near-fatal wounds in only two months. Godzilla’s species have incredibly powerful legs as well as a long developed tail for locomotion, balance, and combat. The species is shown to be highly capable of travel both on land and in water with a max running speed estimated to be 250 KPH and a max swimming speed of 65 knots per hour. The tail can be used effectively as a whip against opponents and sports a sharp modified dorsal near the end capable of tearing through flesh with ease. The species also has incredibly powerful jaws and arms that allow for easy close combat. In addition to these physical abilities, the species also has a variety of more specialized abilities including the following:

Atomic Breath: G-radiation stored in the body runs through the vein structures into the back of the throat where it combines with hydrogen from a specially developed hydrogen sac above the lungs creating a devastating spiral of burning plasma capable of cutting through entire cities, other daikaiju, and even mountainsides with ease.

Nuclear Pulse: G-radiation is quickly expelled from several openings in the body in a large bubble and explodes, causing anything in the surrounding area to be reduced to mere atoms.

Tail Beam: Similar to the Atomic Breath, radiation is fired into the end of the tail and combines with hydrogen, creating a highly focused beam of destruction.

Fission Punch: G-radiation is sent to the fist during a punch and creates explosions and shockwaves upon impact.

More Age of Monsters is on the way soon, so I hope this repost with an updated format will raise your anticipation for the next entry!

#godzilla: age of monsters#godzilla au#artwork#art#godzilla#kaiju#fangoji#godzilla redesign#godzilla fanart#toho kaiju#kaiju art#kaiju redesign#minilla

15 notes

·

View notes

Text

SS 304 Flange: Features, Applications, and Price List

The SS 304 flange is a key component in the world of industrial piping, offering outstanding durability, corrosion resistance, and strength. Whether you're managing a large-scale industrial project or a smaller application, SS 304 flanges play a vital role in ensuring secure and leak-proof connections. In this article, we will explore the features, applications, and pricing of SS 304 flanges, along with the latest SS 304 flange price list. At Udhhyog, we provide high-quality SS 304 flanges at competitive prices to meet all your project needs.

What is SS 304 Flange?

SS 304 flange refers to a flange made from Stainless Steel 304, an austenitic steel known for its excellent corrosion resistance, strength, and versatility. Grade 304 stainless steel is composed of 18% chromium and 8% nickel, making it highly resistant to rust and other forms of corrosion in both mild and harsh environments.

Flanges are used to connect pipes, valves, pumps, and other equipment in piping systems, ensuring a secure seal and facilitating easy assembly, disassembly, and maintenance. The SS 304 flange is one of the most commonly used types of stainless steel flanges in industries like oil and gas, chemical processing, food production, and water treatment.

Key Features of SS 304 Flanges

Corrosion Resistance The high chromium and nickel content in SS 304 flanges makes them resistant to corrosion from chemicals, moisture, and gases, making them ideal for both indoor and outdoor applications.

Heat Resistance SS 304 flanges can withstand high temperatures, making them suitable for steam lines, hot water systems, and other high-temperature applications.

Strength and Durability SS 304 flanges offer excellent mechanical strength, ensuring reliable performance even under high pressure. They are durable, long-lasting, and require minimal maintenance.

Ease of Fabrication These flanges are easy to weld and machine, allowing for customization based on specific project requirements. Whether you need special dimensions or configurations, SS 304 flanges are highly adaptable.

Versatility From chemical plants to marine environments, SS 304 flanges are used in a wide range of industries due to their resilience and ability to perform in extreme conditions.

Applications of SS 304 Flanges

SS 304 flanges are used in various industrial sectors, including:

Chemical Processing: With their ability to withstand corrosive chemicals and extreme temperatures, SS 304 flanges are frequently used in chemical plants and processing facilities.

Food and Beverage Industry: The sanitary properties of SS 304 make it a popular choice for food processing and packaging systems.

Oil and Gas Industry: The durability and resistance to corrosion make SS 304 flanges ideal for pipelines in the oil and gas sector.

Water Treatment: In water treatment plants, where corrosion and exposure to water are constant, SS 304 flanges provide reliable, long-lasting performance.

Pharmaceutical Industry: These flanges are suitable for pharmaceutical applications due to their hygienic properties and resistance to contamination.

Factors Influencing SS 304 Flange Prices

When considering the price of SS 304 flanges, several factors can affect the cost. Here's what you should consider:

Material Costs Fluctuations in the price of stainless steel raw materials, especially nickel and chromium, can impact the price of SS 304 flanges.

Size and Type of Flange Larger flanges or those with specialized designs (such as weld neck, slip-on, or blind flanges) are typically priced higher due to the additional material and labor required for production.

Surface Treatment and Finishing Flanges with additional surface treatments, such as polishing or galvanization, may have a higher price, especially if intended for use in corrosive environments.

Manufacturing Precision SS 304 flanges that undergo precision manufacturing processes, such as forging or CNC machining, are generally priced higher, but they offer superior performance and quality.

Quantity Bulk purchases usually offer better pricing. At Udhhyog, we provide attractive discounts for bulk orders, making our flanges more affordable for large-scale projects.

Market Demand Market conditions and demand for stainless steel products can also affect the price of SS 304 flanges.

SS 304 Flange Price List

Here’s a general price overview for common sizes of SS 304 flanges:

1 inch SS 304 flange: ₹300 to ₹650 per piece

2 inch SS 304 flange: ₹400 to ₹850 per piece

3 inch SS 304 flange: ₹600 to ₹1,400 per piece

4 inch SS 304 flange: ₹900 to ₹2,100 per piece

6 inch SS 304 flange: ₹1,600 to ₹3,500 per piece

Please note that these prices are subject to change based on market trends, material costs, and supplier terms. For an accurate and up-to-date SS 304 flange price list, we encourage you to contact Udhhyog directly.

Why Choose Udhhyog for SS 304 Flanges?

At Udhhyog, we are committed to providing high-quality SS 304 flanges at the most competitive prices. Here’s why businesses trust us:

Superior Quality: Our flanges are manufactured using premium-grade SS 304 stainless steel, ensuring maximum durability and performance.

Affordable Prices: We offer some of the most competitive prices in the market, along with bulk purchase discounts.

Customization: We can customize the dimensions and finishes of flanges to meet your project’s specific requirements.

Strict Quality Control: All our flanges undergo rigorous quality checks to ensure they meet industry standards for performance and safety.

Timely Delivery: Our streamlined supply chain ensures that orders are delivered on time, helping you stay on schedule.

2 notes

·

View notes

Text

1/13

Packs on the Pounds -

Fast food is convenient and cheap, but you pay a bigger price in the long run. Those burgers, fries, and shakes usually have more fat, calories, and highly processed carbs than your body needs in one meal. This can quickly lead to weight gain and obesity if you eat it often.

2/13

Harms Your Heart

Sodium makes fast food taste better and keeps it from spoiling. But just one bacon cheeseburger can contain your recommended daily value for sodium. That’s the amount of a nutrient experts suggest getting every day. Too much sodium raises your blood pressure and damages your blood vessels. It also raises your risk for heart failure, heart attack, and stroke.

3/13

Spikes Blood Sugar

Bagels, buns, and breaded foods are high in processed carbs your body breaks down into sugar. As blood sugar levels rise, your body pumps out insulin to level things out. Over time, these constant sugar spikes can wear out your pancreas (the organ that makes insulin). This keeps blood sugar levels high, triggering type 2 diabetes.

4/13

Opens the Door to Digestive Issues

Fast food may taste good, but you may not feel well once it hits your system. High-sodium foods (fries, anyone?) can temporarily trigger bloat. Couple that with low amounts of dietary fiber, and your digestive tract gets backed up. This can lead to constipation that puts you at risk for hemorrhoids, hernias, and diverticulitis.

5/13

Affects Your Mood

What you eat and drink can impact how you feel mentally and physically. Fast food lacks the vitamins, minerals, and other nutrients your body needs to boost your mood. Research suggests fast and processed foods you buy at the store may be linked to a higher risk of depression.

6/13

Makes You Tired

When a bunch of processed carbs hit your system, your blood sugar rises quickly, then drops just as fast. This can make you feel tired. If you grab a sugary coffee drink to wake up, the cycle starts all over again.

7/13

Could Impact Your Fertility

Phthalates, synthetic chemicals that dissolve materials and make plastics durable, are in everything from toys to fast food. Recent studies have linked phthalates with fertility issues and higher risks of learning and behavioral disorders in children.

8/13

Changes Your Bathroom Habits

Because it’s highly processed, fast food -- especially the kind that’s fried or creamy -- can be hard to digest. If your body can’t break it down, it lands in your colon and turns into fatty acids that spark diarrhea.

9/13

Invites Dental Disease

The high levels of carbs and sugar in fast food, including sodas, raises the amount of acids in your mouth. These wear down the enamel on your teeth and boosts your risk of cavities, tooth decay, and gum disease.

10/13

Wears Out Your Bones and Joints

Excess weight and obesity caused by fast food puts extra pressure on your joints, especially your hips and knees. This makes you more likely to get fractures in the bones around your joints.

11/13

Raises Your Risk for Respiratory Issues

One fried chicken dinner won’t affect the way you breathe. But too much fast food can lead to extra weight that increases your risk of asthma, especially in women. More research is needed to know exactly why, but early studies show that fat tissue leads to inflammation that may affect your lungs.

12/13

Causes Skin Outbreaks

Fast food is full of ingredients that don’t play well with your skin. Sugar can lower collagen levels and lead to signs of early aging, like wrinkles. Salt drains moisture from your skin, but it helps your body keep the water that causes bags under your eyes. High amounts of saturated fats trigger hormones that play a role in acne.

13/13

Affects Your Memory

Experts think saturated and trans fats tell your body to make plaques in the brain. These cause dementia and raise your risk of Alzheimer’s disease three times more than those who don’t eat fast food.

#13 Things Fast Food Does to Your Body#fastfood#depression#bad skin#diet of fat and salt#sugar#bones and joints#arthritis#diabetes#blood sugar spikes#Bad Diet

2 notes

·

View notes

Text

2024 to learn to use the new refrigeration technology technology to ensure the continuous freshness of vegetable food

With the development of modern society, refrigeration technology plays an increasingly important role in our daily lives. From home air conditioning to commercial refrigeration, from the medical cold chain to food processing, refrigeration technology is used everywhere. In this field, professional refrigeration technology has become the key to promote the development of the industry and bring comfort and convenience to our lives.

The importance of specialized refrigeration technology cannot be overstated. First of all, it provides a comfortable temperature for our living and working environment. In the hot summer, air-conditioning systems can bring us coolness and comfort, and the support and innovation of professional refrigeration technology is indispensable behind these refrigeration equipments.

Secondly, specialized refrigeration technology also plays an important role in food preservation and healthcare. In food processing and refrigerated transportation, refrigeration technology can extend the shelf life of food and ensure its freshness and safety. In the medical field, cold chain transportation and refrigeration equipment ensure the quality of medicines and vaccines, and play a vital role in disease control and prevention.

The development of specialized refrigeration technology is dependent on technological innovation and continuous progress within the industry. For example, advanced compressor technologies such as Semi-Hermetic compressors, Scroll compressors and Screw compressors, as well as various types of condensing unit products, are all important components of specialized refrigeration technology. The continuous innovation and enhancement of these technologies has brought about a huge improvement in the performance, efficiency and reliability of refrigeration equipment, as well as a better user experience. Next, let's discover the various types of refrigeration compressor models:

Semi-Hermetic compressor, this compressor is compact, suitable for small and medium-sized refrigeration systems, with high reliability, easy maintenance and so on. The company's Semi-Hermetic compressor is widely used in commercial refrigeration and freezing equipment, industrial refrigeration equipment and other fields, well received by consumers.

Scroll compressor, another product that has attracted a lot of attention is it. This compressor adopts advanced scroll compression technology, featuring smooth operation, low noise and high efficiency. It is widely used in air conditioning, heat pumps, commercial refrigeration equipment and other fields, and can provide reliable refrigeration solutions.

Screw Compressor, this kind of compressor is suitable for large refrigeration system, with high efficiency and good stability, etc. Screw Compressor is widely used in industrial refrigeration, cold storage, cold chain logistics and other fields, which can provide very powerful refrigeration capacity.

Reciprocating Compressor is also a common refrigeration equipment, which is used to inhale low-temperature and low-pressure vapors, increase their temperature and pressure through compression, and then discharge the high-temperature and high-pressure vapors. This type of compressor is commonly used in refrigeration systems, including domestic refrigerators, commercial cold storage equipment, air conditioning systems, industrial refrigeration equipment, and more. This type of compressor is usually characterized by simple structure, high reliability, large refrigeration capacity, etc., and is suitable for refrigeration systems of various sizes.

Condensing Unit, this is in addition to compressor products, various other types of condensing unit products. These units are compact, stable performance, can be widely used in commercial refrigeration and freezing equipment, catering cold storage and other occasions, can provide comprehensive refrigeration solutions.

In addition to the above, there are more 2024 new refrigeration technology products waiting for you to discover, now immediately click to learn more: https://youtu.be/SlXrf5VmqsE?si=u7y4viIEIax98Oi2

original resource:https://youtu.be/SlXrf5VmqsE?si=u7y4viIEIax98Oi2

2 notes

·

View notes

Text

"A Guide to Keeping Your Heart Healthy: Simple Steps for a Healthier Life"

Introducing the Healthy Heart Solution Kit:

To support your heart health journey, you may want to consider the "Healthy Heart Solution Kit." This comprehensive kit is designed to help you maintain a healthy heart through natural, science-backed methods. It includes:

To get full details click here

Heart-Boosting Supplements:

These supplements are packed with essential vitamins and minerals that support heart health. They can help reduce inflammation, lower cholesterol levels, and promote overall cardiovascular wellness.

2. Healthy Eating Guide:

A detailed guide that provides you with meal plans and recipes to follow a heart-healthy diet. It also includes tips on portion control and making smart food choices.

3. Exercise Plan:

A customized exercise plan that's suitable for your fitness level and designed to improve heart health. Regular workouts can strengthen your heart muscle and reduce the risk of heart disease.

4. Stress Management Techniques:

This part of the kit provides techniques and practices to help you manage stress effectively. Stress reduction is essential for maintaining a healthy heart.

5. Quit Smoking and Alcohol Cessation Guide:

If you smoke or consume alcohol excessively, these guides can be incredibly helpful in breaking these habits, which are detrimental to your heart.The Healthy Heart Solution Kit is a convenient and comprehensive resource to help you on your journey to a healthier heart. By incorporating its components into your daily routine, you can reduce the risk of heart diseases and improve your overall well-being.

Get this amazing product by clicking here<<

Your heart is a remarkable organ, tirelessly pumping blood throughout your body to keep you alive. It plays a crucial role in maintaining your overall health and well-being. However, with the hectic pace of modern life and unhealthy lifestyle choices, heart problems have become increasingly common. The good news is that you can take simple steps to keep your heart healthy and reduce the risk of heart diseases. In this article, we'll explore some easy-to-follow tips to maintain a healthy heart and introduce you to a product, the "Healthy Heart Solution Kit," that can support your heart health journey.

Eat a Balanced Diet:

Maintaining a heart-healthy diet is essential. Focus on consuming a variety of fresh fruits and vegetables, whole grains, lean proteins, and healthy fats. Limit your intake of processed foods, sugary drinks, and excessive amounts of salt. A balanced diet can help regulate your cholesterol levels, blood pressure, and weight, all of which are key factors in heart health.

Exercise Regularly:

Regular physical activity is crucial for maintaining good heart health. Aim for at least 150 minutes of moderate-intensity aerobic exercise, such as brisk walking, swimming, or cycling, per week. Exercise helps strengthen your heart, improve blood circulation, and maintain a healthy weight. Additionally, it can reduce stress and improve your overall well-being.

Manage Stress:

Stress can take a toll on your heart, so it's important to find healthy ways to manage it. Consider practicing relaxation techniques like deep breathing, meditation, or yoga. Taking time for yourself, pursuing hobbies, and spending quality time with loved ones can also reduce stress and promote a healthy heart.

Avoid Smoking and Excessive Alcohol:

Smoking is a major risk factor for heart disease, as it damages blood vessels and increases the risk of blood clots. If you smoke, seek help to quit. Also, limit alcohol consumption, as excessive drinking can lead to high blood pressure and other heart-related issues.

Get Sufficient Sleep:

Aim for 7-9 hours of quality sleep each night. Inadequate sleep can contribute to obesity, high blood pressure, and other heart problems. A consistent sleep schedule and a comfortable sleep environment can help improve your sleep quality.

If you want your heart, healthy please click here<<

#how to start a healthy lifestyle#foods to avoid for a healthy heart#how to lead a healthy lifestyle#19 simple everyday tips for a healthier life#healthy eating#healthy lifestyle#tips for a healthier life#how to be healthy#how to start eating healthy (life changing)#healthy habits for a better you#tips to living a healthier lifestyle#18 simple ways to make your daily diet healthier#how to live a healthier lifestyle#how to live a healthier life#tumblr

2 notes

·

View notes

Text

Japan’s plan to release more than 1 million tons of treated radioactive water from the Fukushima nuclear power plant into the Pacific Ocean has set off a firestorm among neighboring countries and raised concern among international nuclear safety experts.

The U.N. nuclear watchdog International Atomic Energy Agency (IAEA) released a report last week that said the plan met international standards, though the atomic agency did not endorse or recommend the Japanese disposal idea. IAEA Director-General Rafael Grossi said Japan must make the final decision on whether to proceed with the water disposal plan, which is expected to start as early as August. The report assessed that the discharge would have “negligible radiological impact on people and the environment.”

“We do not take sides,” Grossi told Reuters. “I’m not on the side of Japan or on the side of China or on the side of Korea. The standards apply to all the same way.”

A spokesperson from the Chinese Foreign Ministry said on July 7 that the IAEA’s report failed to address international concerns on the impact of treated wastewater on people and the environment, urging Japan to “give up using the IAEA report as the ‘greenlight’” and handle the contaminated water in a responsible way. The same day, China’s General Administration of Customs announced that it would continue its previous ban on imported food from Fukushima and nine other regions, as well as increase regulation of imported food from other parts of Japan.

Similar sentiments have festered in South Korea despite the current Korean administration’s support of the plan. Hundreds gathered in Seoul last weekend to protest against the Fukushima water disposal plan while opposition lawmakers spoke with Grossi in a tense meeting to voice their concerns. South Korea also plans to stick with its ban on all seafood imports from eight Japanese regions around Fukushima, which has been in place since 2013. Fish markets in South Korea have increased testing of seafood for radiation, and shoppers are hoarding salt as fears have grown over the Fukushima water release.

The plan, however, has found some backing in other countries such as the United States, which praised Japan for working with the IAEA to conduct a “science-based and transparent process.” The European Union is soon expected to lift all restrictions on food imports from Japan, while Taiwan lifted its ban in 2022.

Japanese officials continue to defend the neutrality of the IAEA report against claims that Tokyo pressured the agency to publish only positive reviews of the plan. A spokesperson from the Japanese Embassy in Washington told Foreign Policy the IAEA’s report was a result of independent and neutral review that shows Tokyo Electric Power Company (TEPCO), the Fukushima plant operator, has demonstrated a “high level of accuracy in their measurements and technical competence.”

“The Government of Japan will continue to provide necessary information to the international community, including neighboring countries, in a transparent manner, and will make efforts to foster further international understanding of the handling of ALPS treated water,” he said.

A massive earthquake and tsunami destroyed the Fukushima Daiichi Nuclear Power Plant in 2011, causing the reactor cores to overheat and contaminate water with highly radioactive material. Ever since, workers have pumped more water into the plant to cool the reactor cores and gathered the contaminated water into more than 1,000 tanks that the Japanese government says must now be disposed of to prevent any accidental leaks.

But marine biology and radiochemistry experts say the IAEA’s assessment is by no means comprehensive and note that the current lack of data raises questions over Japan’s handling of the disposal.

Much of the discussion surrounds a radioactive material in the water called tritium, which cannot be removed by the treatment system and must be diluted before being dumped into the ocean. But experts said their worry is not necessarily about the levels of tritium entering the marine ecosystem, but the other radioactive material not cited in the report, including iodine-129 and cobalt-60.

“There is a tremendous difference among different radionuclides in their bioaccumulation or environmental behavior. This is often overlooked,” Wen-Xiong Wang, the chair professor of environmental toxicology at City University of Hong Kong, said.

Although tritium’s water-like nature means that it does not easily accumulate in the ocean, cobalt-60 is 300,000 times more likely to accumulate with other seafloor sediments, and strontium-90 behaves similarly to calcium and can end up in fish bones, said marine radiochemist Ken Buesseler, who has conducted research at the Fukushima site and continues to follow the site’s progress.

IAEA spokesperson Fredrik Dahl said that the IAEA will continue to independently sample and analyze the treated water, seawater, and fish, as well as review the sampling done by TEPCO but maintains that current radioactive levels meet safety standards.

TEPCO released data in 2018 that revealed the presence of more dangerous radioactive elements, requiring more than 70 percent of the tanks to undergo secondary treatment to reduce radioactive concentrations. While these concentrations are “orders of magnitude lower than tritium,” they are “highly variable from tank to tank,” according to a 2020 study published by Buesseler in Science Magazine. And he said that there are still many tanks that have either never been analyzed or reported by TEPCO.

“I’m not saying [radioactive] levels will exceed standards, but how will [the Japanese government] know? Their assessment plan of what’s in the tank is woefully inadequate,” Buesseler, who currently works as a senior scientist at Woods Hole Oceanographic Institution, said. “They talk about measuring tritium, cesium, but very little else, and they haven’t demonstrated that they can do those measurements adequately with enough sensitivity.”

A spokesperson from the Japanese Embassy in Washington said all monitoring results made by TEPCO, IAEA, and third party laboratories are made public.

Buessler and other experts urged the Japanese government to consider other alternatives, such as solidifying the wastewater into concrete, which would trap the tritium and also help expand the sea wall that would serve as a tsunami barrier.

“This is the kind of ‘trust us we’ll take care of it plan,’ and I just feel like they haven’t built up that level of trust to be given approval,” Buesseler said.

3 notes

·

View notes

Text

A hydraulic sausage stuffer is a machine used to fill sausage casings with ground meat or other materials

It uses hydraulic pressure to push the meat through a nozzle and into the casing. The machine typically consists of a hopper, a hydraulic cylinder, a piston, and a nozzle. The operator loads the hopper with the ground meat and activates the hydraulic pump, which generates pressure to push the piston forward and extrude the meat through the nozzle and into the casing. Hydraulic sausage stuffers are typically used in commercial or industrial settings, where large volumes of sausage are produced. They offer advantages over manual or electric sausage stuffers, including faster production times, greater consistency, and improved efficiency.

A bowl chopper is a piece of commercial kitchen equipment used to chop and emulsify meat, vegetables, and other food items. It consists of a large bowl that rotates on a central axis, with a series of sharp blades mounted on the bottom of the bowl. The operator loads the food items into the bowl and activates the machine, which spins the blades at high speed to chop and mix the ingredients. The bowl chopper can be used to make ground meat, sausages, pâtés, and other processed foods.

Bowl choppers are commonly used in commercial kitchens, such as butcher shops, delis, and food processing plants, where large quantities of meat and other ingredients need to be processed quickly and efficiently. They offer several advantages over other chopping methods, including greater consistency, faster processing times, and improved texture and flavor. Bowl choppers can also help reduce labor costs and minimize waste by using the entire food item, including bones and other scraps.

Commercial meat mixers are machines used to mix and blend ground meat and other ingredients. They are commonly used in commercial and industrial settings, such as butcher shops, meat processing plants, and food manufacturing facilities. The mixers typically consist of a large mixing bowl or hopper, a mixing blade or paddle, and a motor to power the mixing action.

The operator loads the ingredients into the mixing bowl or hopper and activates the machine, which rotates the mixing blade or paddle to blend the ingredients together. Some models may offer additional features such as variable speed settings, timers, and reverse mixing capabilities. Commercial meat mixers are available in a variety of sizes and capacities to meet the needs of different operations.

Commercial meat mixers

offer several advantages over manual mixing methods, including faster processing times, greater consistency, and improved food safety. They can also help reduce labor costs and improve efficiency by allowing operators to mix large batches of ingredients at once. Commercial meat mixers are typically made of durable materials such as stainless steel, which makes them easy to clean and maintain.

2 notes

·

View notes

Text

The Importance of Pump Maintenance in Food & Beverage Manufacturing

The food and beverage manufacturing industry requires high-pressure food processing pumps to maintain product quality, operational efficiency, as well as safety standards. Periodic pump maintenance has the additional benefit of not only extending the life of the equipment but also preventing costly downtimes of production.

But first just like any machine pump also needs maintenance for efficient performance. Failure to maintain pumps in good condition leads to a series of effects ranging from reduced productivity to increased food contamination and ultimately losses in the business.

Why Pump Maintenance Matters?

High-pressure food processing pumps can be used in pasteurization, homogenization, and transferring viscous fluids during food processing. These pumps are developed for operating in this industry but being machines they need maintenance for efficient performance.

The Importance of Pump Maintenance

Ensures Consistent Product Quality: Maintained pumps ensure that there is uniformity in how products are processed and that the products conform to high standards of quality. When there is a failure in the performance of the pump then this will result in the production of inconsistent products which will contribute to consumer dissatisfaction and damage the brand image.

Prevents Contamination: In the food and beverage industry, hygiene is of great importance. Routine maintenance can also help reduce the risk of leaks that may cause contamination. This applies especially to high-pressure pumps in industries such as pasteurization where the conditions must be sterile.

Reduces Downtime: Unscheduled downtime can be extremely costly for manufacturers. Preventive maintenance also enables identifying possible failures before they occur and thus prevents unexpected stoppages and contributes to uninterrupted operation.

Extends Equipment Life: Routine maintenance helps to extend the life of high-pressure food processing pumps from wear and tear. This can lead to significant cost-savings on replacements or major repairs.

Compliance with Regulations: The food and beverage industry is subject to strict regulatory standards. Regular maintenance ensures that pumps operate within the required parameters, helping manufacturers comply with industry regulations and avoid penalties.

Maintenance Best Practices for Food & Beverage Pumps

Schedule regular inspections: Develop a preventive maintenance schedule based on the pump's usage and the manufacturer's recommendations.

Clean and Sanitize: Food-grade cleaning and sanitation procedures are crucial to maintain hygiene standards.

Inspect Seals and Bearings: Regularly check seals and bearings for wear and tear to prevent leaks and ensure smooth operation.

Lubricate as Needed: Proper lubrication reduces friction and wear on critical components, extending pump life.

Invest in Training: Ensure your staff is trained on proper pump operation and maintenance procedures.

Real-World Example: Dairy Processing in India

Let's take an example of a dairy processing plant in rural Maharashtra. Here, high-pressure food processing pumps are operated in large numbers for pasteurization and homogenization. The plant also has a maintenance strategy for its pumps to maintain the consistent quality of the dairy products.

Major maintenance consists of weekly checks, monthly oiling and a quarterly clean of the pumps. Moreover, it uses a performance monitoring system to detect the condition of the pumps and rectify them before any failure. This preventative culture has also led to a decrease in downtime, increases in product quality, and adherence to food safety regulations. Thus increasing the overall business productivity.

Conclusion

Regular maintenance of high-pressure food processing pumps is essential for the success of food and beverage manufacturing operations. By ensuring consistent product quality, preventing contamination, reducing downtime, extending equipment life, and complying with regulations, proper pump maintenance can provide significant benefits to manufacturers.

For expert assistance in maintaining your high-pressure food processing pumps, contact Fristam Pumps (India) Pvt Ltd. Our comprehensive maintenance services and industry expertise can help ensure your pumps operate at peak performance, driving efficiency and quality in your manufacturing processes.

FAQs:

1) What is the importance of having maintenance on pumps?

Pump maintenance ensures food safety (prevents leaks, and contamination), optimizes performance (reduces energy costs, avoids breakdowns) and extends pump lifespan (saves money on replacements).

2) Why are pumps important in the food industry?

Food industry pumps are crucial for moving ingredients, maintaining hygiene (sanitation processes), and ensuring efficient production flow.

3) What are the common types of pumps used in food and beverage manufacturing?

Common food and beverage manufacturing pumps include:

Positive displacement pumps (e.g., rotary lobe pumps) for handling thick liquids and pastes.

Centrifugal pumps for efficient transfer of liquids like juices and beverages.

Sanitary pumps are designed for easy cleaning and sterilization to meet hygiene standards.

4) What are the best practices for pump maintenance in the food and beverage industry?

Best practices for food & beverage pump maintenance include:

Regular inspections and cleaning/sanitation.

Checking seals and bearings for wear.

Proper lubrication.

Staff training on pump operation and maintenance.

#high-pressure food processing pumps#centrifugal pump manufacturers in india#hygienicpumps#industrial centrifugal pump manufacturers in india#fristampumps

0 notes

Text

type ii diabetes is a systemic problem with multiple factors. diet is only one of them. the above post mentions genetics. activity level and stress are another.

i feel the need to say this because there are a lot of people who don't realize the correlation between type ii diabetes risk and the suburban car-oriented lifestyle. i see middle class people who have the means to prevent it, getting type ii diabetes and sometimes realizing it too late to where it majorly shortens their lifespans and contributes to high medical costs and a greatly reduced quality of life. this has happened to the parents of a disturbing number of my friends as well as random older adults i know.

mainstream society glorifies and normalizes various types of stress, including workplace stress from a fast-paced or high-pressure career, and relationship stress which can be worsened by poor communication patterns.

it also glorifies and normalizes a car-oriented lifestyle and, in the US, practically forces this lifestyle on people

to combat type ii diabetes we really need a systemic, public health approach that includes changes like removing agricultural subsidies on refined or heavily processed foods that basically pump cheap sugar and corn syrup and refined starches into the food supply. and we also need reform that stops spending money on and mandating car-oriented infrastructure and instead creates communities designed around walk+bike+transit.

we need to move away from the culture of shaming individuals for their personal choices, and address the societal issues

I’m so fucking sick of diabetes jokes. They’re everywhere, like people somehow think it’s ok to make fun of a disease like that.

“that’s got so much sugar, it’ll give you diabetes!”

first of all THATS NOT HOW ANY TYPE OF DIABETES WORKS.

Second of all, even if it was, and people ‘gave diabetes to themselves’, it’s just not funny! Who gave you the right to make fun of a literal disabled person just because you think they deserve it because they ‘brought this onto themselves’? that’s fucked up! All types of diabetes have a genetic component, and specifically for type 2 diabetes, you don’t know that person’s circumstances. Recent studies are showing links between type 2 diabetes and poverty, as sugary overprocessed food like fast food is cheaper and sometimes more accessible. And once again, there’s still a genetic component.

‘that’ll give you diabetes’ jokes are just not funny. They’re insensitive, and as a type 1 they’re just a constant reminder that I have a disease that is heavily misunderstood and weighs on me every day. I’ve heard like 10 in the past week and just now heard another one and it was the last fucking straw. DON’T MAKE THEM.

39K notes

·

View notes

Text

Rubber Products Manufacturer: A Comprehensive Overview

Arvico is one of India’s leading rubber products manufacturers, exporters, and suppliers specializing in producing rubber diaphragms, rubber sleeves, PTFE components, rubber couplings, and rubber O-rings, among others. With over 50 years of experience, our brand offers customized components that precisely match your needs. We take pride in never compromising on quality, ensuring customer satisfaction and trust.

With a combined rubber industry experience spanning several hundred years, our team takes full ownership of rubber product manufacturing and its applications. We are dedicated to supporting you at every stage, ensuring high-performance solutions tailored to various industries. Passionate about our field, we are committed to delivering innovative rubber solutions that help businesses grow.

Industries Served

Arvico serves a diverse range of industries, including:

Pharmaceutical

Packaging

Oil & Gas

Food Processing

Nuclear

Electrical

Paper Industry

Chemical Processing

Textile Industries

Engineering

Medical & Life Sciences

Construction

Rubber Products and Applications

Rubber Diaphragms

Rubber diaphragms are flexible barriers that provide pressure control in mechanical and fluid systems. Manufactured using high-quality rubber compounds, they are essential in regulating flow, ensuring sealing, and preventing contamination in critical environments. These diaphragms are widely used in pumps, valves, actuators, and control systems where precision and durability are paramount.

Applications:

Utilized in automotive braking systems to enhance pressure modulation.

Used in industrial pumps to maintain fluid integrity and prevent leaks.

Found in medical equipment to enable controlled fluid dispensing.

Rubber Sleeves

Rubber sleeves serve as protective barriers against environmental damage, electrical currents, and mechanical wear. They offer resistance to high temperatures, chemicals, and abrasion, ensuring long-term functionality in demanding applications. Manufactured in various sizes and compositions, rubber sleeves help safeguard critical components across industries.

Applications:

Used in electrical insulation to prevent current leakage and improve safety.

Applied in industrial machinery to reduce vibration and mechanical wear.

Incorporated into automotive systems to protect wires and hoses from external damage.

PTFE Components

PTFE Components are known for their exceptional chemical resistance, high thermal stability, and low friction properties. PTFE (Polytetrafluoroethylene) are widely used in demanding applications where exposure to harsh chemicals, extreme temperatures, and pressure fluctuations is common.

Applications:

Found in chemical processing plants to ensure corrosion-resistant piping systems.

Used in food and beverage manufacturing to maintain hygiene and prevent contamination.

Integrated into medical devices to enhance biocompatibility and durability.

Rubber Couplings

Rubber couplings are essential for flexible power transmission, helping to absorb shocks, vibrations, and misalignments in mechanical systems. These couplings improve operational efficiency while reducing maintenance needs and extending equipment lifespan.

Applications:

Used in industrial machinery to ensure smooth torque transmission and minimal vibration.

Found in automotive drive systems to enhance flexibility and reduce mechanical stress.

Employed in HVAC systems to prevent misalignment issues and ensure smooth operation.

Rubber O-Rings

Rubber O-rings are crucial for sealing applications, preventing leaks, and ensuring fluid retention in hydraulic and pneumatic systems. Available in various elastomeric materials, they provide excellent resistance against heat, chemicals, and pressure fluctuations.

Applications:

Used in hydraulic cylinders and pumps to create airtight seals.

Applied in aerospace engineering for fuel system integrity.

Essential in medical equipment to prevent contamination in fluid-handling systems.

Rubber Expansion Joints

Rubber expansion joints help absorb movement, reduce vibration, and compensate for thermal expansion in piping systems. They provide flexibility while maintaining system integrity, making them indispensable in fluid transport applications.

Applications:

Installed in HVAC duct systems to prevent stress from thermal expansion.

Used in chemical plants to manage pipeline movement and reduce strain.

Applied in bridge construction to allow structural expansion and contraction.

Rubber Bearing Bushes

Rubber bearing bushes act as vibration dampeners and shock absorbers in mechanical assemblies. Their ability to isolate noise and motion makes them essential in precision engineering and heavy-duty machinery.

Applications:

Used in automotive suspension systems to enhance ride comfort.

Incorporated into industrial equipment to mitigate mechanical stress.

Found in railway applications to improve track stability and reduce maintenance needs.

Rubber Gaskets

Rubber gaskets provide excellent sealing properties, preventing leaks and protecting machinery from contamination. They are manufactured in various shapes and sizes to meet the specific needs of different applications.

Applications:

Used in engines and machinery to prevent oil and coolant leaks.

Applied in pipelines to ensure tight sealing in high-pressure environments.

Essential in the food industry to maintain hygiene and prevent cross-contamination.

Extruded Rubber Profiles and Cords

Extruded rubber profiles and cords are custom-shaped elastomeric components used in sealing, insulation, and impact absorption. Their versatility allows them to be used across various industries.

Applications:

Utilized in construction to provide weatherproofing for doors and windows.

Found in marine applications to prevent water ingress in boats and ships.

Applied in automotive seals to enhance durability and noise reduction.

Moulded Rubber Parts

Moulded rubber parts are custom-designed components manufactured to meet specific industrial requirements. These parts ensure high precision and durability in various applications.

Applications:

Used in aerospace engineering for vibration damping and sealing solutions.

Found in agricultural machinery to enhance performance and longevity.

Integrated into electronic devices for insulation and impact resistance.

Rubber Hoses

Rubber hoses facilitate fluid transfer, offering flexibility, pressure resistance, and chemical stability. They are used in various sectors, from automotive to industrial processing.

Applications:

Essential in fuel delivery systems to ensure leak-proof fluid transport.

Used in hydraulic systems for efficient power transmission.

Incorporated in firefighting equipment to handle high-pressure water discharge.

Rubber Sheets

Rubber sheets offer high resistance to abrasion, impact, and environmental factors. They are used for flooring, insulation, and protective applications.

Applications:

Used in industrial flooring to provide slip resistance and cushioning.

Applied in gasket manufacturing to create custom sealing solutions.

Essential in construction to prevent structural wear and corrosion.

Conclusion

Arvico takes pride in offering top-quality rubber products that cater to a wide range of industries. Our commitment to innovation, durability, and performance has positioned us as a leading rubber product manufacturer in India. Whether you require custom rubber components or industry-specific solutions, Arvico is your trusted partner in delivering excellence.

youtube

0 notes

Text

Choosing the Right Pump for Your Industry: Ace Lobe Pump vs. Rotary Lobe Pump

In industrial fluid handling, selecting the appropriate pump is crucial for maintaining efficiency and ensuring the longevity of the system. Pumps are designed to transport a variety of liquids, from viscous substances to those containing solids, and they must operate reliably under demanding conditions. The Ace Lobe Pump and the Rotary Lobe Pump are two popular options that stand out for their precision and versatility. This article will explore their unique features, helping industries determine which pump best meets their needs.

Understanding the Ace Lobe Pump

The Ace Lobe Pump is a type of positive displacement pump that uses rotating lobes to transfer liquids efficiently. Its design makes it ideal for handling viscous or shear-sensitive fluids, such as those found in the food, cosmetic, and pharmaceutical industries. The Ace Lobe Pump offers a gentle pumping action that helps preserve the integrity of the liquid being transferred, making it perfect for delicate substances like creams, sauces, and pastes. Its ability to maintain consistent flow with minimal pulsation ensures smooth operations, which is crucial for industries that prioritize quality and consistency in their products.

Why Choose the Ace Lobe Pump?

One of the major advantages of theAce Lobe Pump is its versatility in handling various fluid types. From low-viscosity liquids to thick, viscous materials, this pump can handle them with ease. Its positive displacement technology ensures that a consistent volume of fluid is pumped at each cycle, preventing fluctuations in pressure and maintaining flow rates. This makes the Ace Lobe Pump a reliable option for industries that require precise fluid management. The ability to handle shear-sensitive liquids without causing damage further adds to its appeal, ensuring that sensitive products maintain their integrity throughout the pumping process.

The Rotary Lobe Pump: Robust and Reliable

On the other hand, the Rotary Lobe Pump is known for its robust construction and high-performance capabilities, especially when dealing with more challenging fluids. This pump uses two or more rotating lobes inside the pump chamber to move fluids. It is ideal for applications where the pumped liquid is abrasive, contains solids, or has high viscosity. The Rotary Lobe Pump excels in environments where other pumps might struggle, as it can handle thicker, more complex fluids with ease. Its ability to manage a wide range of substances, from slurries to chemicals, makes it a versatile and durable option for many industries.

Advantages of the Rotary Lobe Pump

The Rotary Lobe Pump stands out in situations where high suction capabilities and minimal pulsation are required. The design allows it to efficiently handle abrasive fluids and those containing high solids content, making it a go-to choice for industries like wastewater treatment, mining, and chemical processing. Its low-maintenance nature and ability to run at high pressures also contribute to its efficiency in harsh conditions. With its minimal pulsation and high suction capabilities, the Rotary Lobe Pump ensures a steady and consistent flow, even under difficult operational circumstances.

Choosing Between the Ace Lobe Pump and Rotary Lobe Pump

When selecting between the Ace Lobe Pump and the Rotary Lobe Pump, industries must consider the specific needs of their fluid systems. The Ace Lobe Pump is ideal for handling shear-sensitive, delicate fluids that require a gentle and consistent flow, making it perfect for food and pharmaceutical applications. Meanwhile, the Rotary Lobe Pump is better suited for industries that deal with more challenging materials, such as abrasive liquids, slurries, or those with solid particles. Both pumps offer significant advantages, but the key lies in understanding the nature of the fluid being pumped and the overall system requirements.

Conclusion

In conclusion, both the Ace Lobe Pump and the Rotary Lobe Pump offer exceptional performance, but their suitability depends on the specific fluid handling needs of a given industry. For gentle, precise pumping of delicate liquids, the Ace Lobe Pump is an excellent choice. On the other hand, for more demanding fluids, the Rotary Lobe Pump provides the necessary robustness and versatility. For more information on these pumps and their applications, visit Acelobepump.com, where more details and solutions are available.

0 notes

Text

The Ultimate Guide to Ultrafiltration Technology and Its Features

UF units operate as state-of-the-art purification systems that use semi-permeable membranes to perform contaminant removal during their separation process. UF systems enable diverse water treatment applications throughout industrial facilities municipalities and domestic settings because they deliver dependable results combined with operational excellence. Ultrafiltration units powered by pressure-driven membrane filtration remove suspended solids and bacteria viruses together with high-molecular-weight substances while letting mineral and smaller molecules pass.

1. Advanced Filtration Technology

Advanced membrane technology stands as the central defining aspect that gives every UF unit its power. UF membranes contain microscopic pores which function between 0.01 and 0.1 microns in size. The membrane's microscopic pore dimensions enable them to separate contaminants including bacteria and viruses and suspended particles and large molecules while permitting unimpeded water and dissolved substance passage. ULF systems surpass traditional filtration by delivering high-grade pure water outputs with no dependency on chemicals so they work well for drinking water production and across industrial applications.

2. Chemical-Free Operation

Ultrafiltration units enable water treatment without requiring chemical additives. The operation of UF processes depends entirely on mechanical filtration without the need for ion exchange or chlorination methods. The systems function independently from chemical dosage requirements which preserves both environmental safety and operational efficiency. The elimination of chemical additives helps protect water quality as it makes water both safe to drink and suitable for all types of uses.

3. High Efficiency in Removing Contaminants

Ultrafiltration systems maintain exceptional capabilities to produce pure water output with every use. These filtration units demonstrate the ability to extract 99% of microbial contaminants which enables their usage in locations with insufficient water quality and in industrial environments requiring extremely pure water. The UF system efficiently removes turbidity together with organic matter and chlorine-resistant microorganisms such as Cryptosporidium and Giardia even though traditional filtration methods struggle with these issues.

4. Flexibility in Uses

Ultrafiltration units are very flexible and can be designed for any specific application. They are widely used in food and beverage, pharmaceuticals, and electronics manufacturing industries, where the purity of the water is critical. Municipalities employ UF systems both for wastewater treatment and for the preparation of drinking water. Currently, UF technology is also becoming very popular for its use in household water purification systems. This adaptability is possible because most UF systems are modularly designed to be scaled up or down based on requirements.

5. Low Energy Consumption

The ultrafiltration units require much lower energy compared with other units of filtration and purification. The low pressure that the process takes applies to lesser energies on water pumping through the membrane. This has provided an energy-efficient solution to large-scale industrial applications and small household purposes. Low power consumption subsequently leads to decreased cost of operation with time, thus making UF systems economically feasible.

6. Low Maintenance Requirements

Ultrafiltration units are also easy to use and maintain. UF membranes are also resilient and last long if they are well maintained; most units contain automatic backwashing mechanisms that can help clean the membranes and maintain them in optimal condition without much intervention. This self-cleaning system helps avoid downtime and maximizes the lifespan of the unit.

7. Compact and Space-Efficient Design

Another essential characteristic of ultrafiltration units is that they are compact in design. The systems occupy a very small area, and their compact design makes them useful for places where there is a constraint on space.

8. Higher Water Recovery Rates

Ultrafiltration systems boast high water recovery rates, with some systems boasting recovery rates over 90%. Unlike reverse osmosis systems that waste large amounts of water, UF units ensure maximum use of the available water supply. This makes them especially valuable in water-scarce areas, as they minimize wastage while providing high-quality output.

Summary

Water treatment technology has taken leaps in the Hinada’s ultrafiltration unit. Right from offering chemically free, energy-efficient low-maintenance, and high-quality water, UF systems are expected to play critical roles that will address the global demand for clean water with such technologies. Being versatile in either residential, industrial, or municipal applications, they incorporate environmentally sustainable features and therefore, stand as indispensable to modern-day water purification.

0 notes

Text

Stainless Steel Silos: Durable and Efficient Storage Solutions for Modern Industries

Stainless Steel Silos: Durable and Efficient Storage Solutions for Modern Industries

In today's fast-paced and competitive industries, efficient storage solutions are paramount. Whether you're dealing with grains, chemicals, powders, or other bulk materials, the right storage system can make all the difference in ensuring smooth operations. Stainless Steel Silos, offered by Shijiazhuang Zhengzhong Technology Co., Ltd. (Center Enamel), provide a durable, reliable, and high-performance solution for bulk storage needs.

Our stainless steel silos are designed to meet the rigorous demands of various industries, ensuring that stored materials remain secure, clean, and easily accessible. With superior corrosion resistance, customizable design, and long-lasting performance, our silos are the ideal choice for businesses that require a high-quality storage solution.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Why Choose Stainless Steel Silos?

1. Exceptional Durability and Corrosion Resistance

One of the primary reasons for choosing stainless steel silos is their exceptional durability and corrosion resistance. Stainless steel is naturally resistant to rust, corrosion, and various chemicals, making it an ideal material for storing bulk materials, especially those exposed to moisture, extreme weather, or harsh environments. This ensures that your stored goods remain safe and intact without the risk of contamination or degradation over time.

2. Hygiene and Cleanliness

In industries such as food processing, pharmaceuticals, and chemicals, maintaining a high standard of hygiene is critical. Stainless steel is non-reactive, smooth, and easy to clean, preventing contamination from external sources. Unlike other materials, stainless steel does not retain odors or residues, ensuring that your stored products remain pure and uncontaminated. This makes stainless steel silos a preferred choice for food-grade storage applications, as they are capable of meeting strict regulatory standards for cleanliness.

3. High Strength and Structural Integrity

Stainless steel is known for its high tensile strength and structural integrity, ensuring that silos can withstand heavy loads and high pressures. Whether you're storing dry or liquid materials, our stainless steel silos offer robust performance, preventing any structural issues that could compromise the safety and efficiency of your storage system.

4. Long-Term Investment and Cost Efficiency

While stainless steel may have a higher initial cost compared to other materials, its long-term performance makes it a cost-effective investment. The corrosion resistance and minimal maintenance requirements ensure that your stainless steel silos will serve you for years to come, minimizing the need for repairs or replacements. This makes them a highly cost-effective solution in the long run.

5. Customizable Design for Specific Needs

At Center Enamel, we understand that different industries have different storage needs. That's why our stainless steel silos can be customized to meet the exact specifications of your business. Whether you need silos for grain storage, liquid storage, chemical storage, or other bulk materials, we offer a variety of sizes, shapes, and features to fit your specific requirements.

Key Features of Center Enamel’s Stainless Steel Silos

1. Superior Corrosion Protection

Our stainless steel silos are designed to provide optimal corrosion resistance, ensuring the longevity and integrity of your storage system. This is particularly important for industries that handle moisture-sensitive or aggressive materials.

2. Hygienic Storage Solutions

The non-porous surface of stainless steel makes it easy to clean and prevents the growth of bacteria, mold, and other contaminants. This feature is essential for food-grade storage and pharmaceutical applications where contamination can lead to significant quality issues.

3. Modular Design for Easy Installation

We offer modular designs for easy transportation and quick installation. This reduces downtime and makes it easier to install large-scale storage solutions with minimal disruption to your ongoing operations.

4. Compliance with Industry Standards

Our stainless steel silos comply with international standards and industry regulations, ensuring that they meet the safety, hygiene, and quality standards required for your industry. Whether you're in the food, chemical, or agricultural sector, our silos are designed to meet your needs.

5. Advanced Safety Features

Our silos are equipped with advanced safety features, including ventilation systems, overflow protection, and level monitoring to ensure smooth and safe storage of materials. These features enhance the safety and efficiency of your storage system, minimizing risks associated with overflows or pressure build-ups.

Applications of Stainless Steel Silos

Stainless steel silos are highly versatile and can be used across various industries for storing bulk materials. Some of the most common applications include:

1. Grain Storage

Grain storage is one of the most common uses of stainless steel silos. These silos offer excellent protection against pests, moisture, and contamination, ensuring that grains remain dry, clean, and safe for consumption or processing.

2. Food and Beverage Industry

The food and beverage industry demands strict hygiene and sanitation standards, which makes stainless steel the perfect material for storing ingredients, powders, and liquids. Stainless steel silos ensure that materials remain uncontaminated and retain their quality during storage.

3. Chemical Industry

In the chemical industry, it's essential to store raw materials and finished products safely. Stainless steel silos offer superior chemical resistance, making them ideal for storing a wide range of chemicals without risk of corrosion or contamination.

4. Pharmaceutical Industry

The pharmaceutical industry requires hygienic and non-reactive storage systems to ensure that materials like active pharmaceutical ingredients (APIs) and other sensitive compounds are stored in a safe environment. Stainless steel silos provide the necessary cleanliness and chemical resistance for such applications.

5. Plastic and Powder Storage

For industries that handle plastics or powders, stainless steel silos provide a secure and efficient storage solution. These silos help maintain the quality of powdered materials while preventing contamination or moisture absorption.

Why Choose Center Enamel for Stainless Steel Silos?

1. Proven Track Record

With over 30 years of experience, Center Enamel is a leading manufacturer of high-quality bulk storage systems. Our stainless steel silos are trusted by industries worldwide for their durability, safety, and performance.

2. Customization and Flexibility

We offer customizable solutions to meet the unique needs of your business. Whether you need a silo for grain, liquid, or chemical storage, we can design and manufacture a solution that fits your exact requirements.

3. International Certifications

Our stainless steel silos meet global standards for safety, hygiene, and environmental compliance. We hold certifications including ISO 9001 and NSF/ANSI, ensuring that our products meet international quality standards.

4. Exceptional Customer Support

At Center Enamel, we are committed to providing exceptional customer support. From the initial consultation to installation and ongoing maintenance, we ensure that you receive the highest level of service at every stage of your project.

Stainless Steel Silos offer a durable, reliable, and hygienic solution for storing bulk materials across various industries. Whether you need to store grains, chemicals, powders, or liquids, Center Enamel provides high-quality silos that meet your specific needs. Our customizable, corrosion-resistant, and easy-to-maintain silos are designed to offer long-term performance and value.

For industries that require secure and efficient storage systems, Center Enamel’s Stainless Steel Silos are the ideal choice. Contact us today to learn more about how our stainless steel silos can meet your storage needs and provide a sustainable solution for your business.

0 notes

Text

Stainless Steel ( S.S ) Rotary Gear Pump Manufacturer | J K Pump Industries

The Stainless Steel Rotary Gear Pump from JK Pumps is a high-quality, durable, and efficient solution for industries requiring smooth and consistent fluid transfer. Engineered with precision, this pump is designed to handle a variety of viscous and semi-viscous fluids, making it an ideal choice for applications in the food, pharmaceutical, chemical, and oil industries. The well-known JK Pump's stainless steel rotary gear pump is made for industrial use, guaranteeing excellent performance and longevity. This S S Rotary Gear Pump is expertly crafted from premium stainless steel, which gives it exceptional corrosion resistance and makes it appropriate for handling a range of liquids, including harsh chemicals, solvents, and oils. This pump is perfect for use in the food processing, oil, chemical, and pharmaceutical industries since it is designed with cutting-edge rotary gear technology to provide steady flow and pressure. Even in challenging applications, its sturdy build and small size allow for seamless integration with your current systems while preserving effective performance.

For More Details Clicks Here - https://www.jkgearpump.com/stainless-steel-rotary-gear-pump-series-jkss/

0 notes

Text

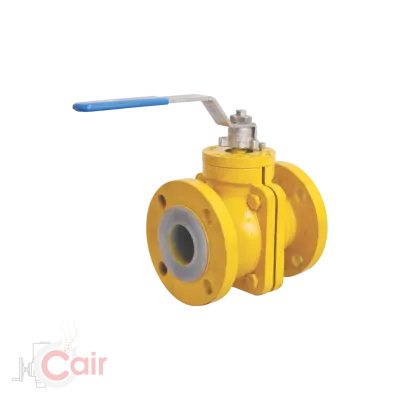

What Is a Ball Valve? A Complete Guide to Its Function and Uses

Ball valves are one of the most commonly used types of valves in industries worldwide. Their design and versatility make them ideal for controlling the flow of various fluids and gases. This comprehensive guide will explore what a ball valve is, how it functions, and its various applications, along with insights into the ball valve manufacturing industry in India.

What is a Ball Valve?

A ball valve is a type of valve that uses a spherical ball to control the flow of media (liquids, gases, or slurries) through a pipe or system. The ball has a hole or port through the center, which aligns with the flow path when the valve is open. When the valve is closed, the ball rotates 90 degrees, blocking the flow path and preventing the passage of the media.

The simplicity of this design allows for quick and efficient operation. Ball valves are known for their durability, reliability, and ability to maintain a tight seal even after long periods of use.

How Does a Ball Valve Work?

A ball valve consists of several key components, including the body, the ball, the stem, and the handle or actuator. The ball is mounted inside the valve body, with the hole or port aligned with the flow path when the valve is open. When the valve handle is turned, the stem rotates the ball, either opening or closing the valve.

The flow direction and the valve's status (open or closed) are determined by the orientation of the ball. In the open position, the flow passes through the hole in the ball, allowing the fluid or gas to move through the valve. In the closed position, the ball rotates 90 degrees, blocking the flow entirely.

One of the key features of ball valves is their ability to create a tight seal. The design ensures minimal leakage, even in high-pressure applications, making them highly reliable in various industries.

Types of Ball Valves

There are different types of ball valves, each suited for specific applications. The most common types include:

Standard Ball Valve: This is the most basic type of ball valve, ideal for simple on/off applications.

V-Port Ball Valve: This valve has a V-shaped ball, which allows for precise flow control, making it suitable for throttling applications.

Multi-Port Ball Valve: These valves have multiple ports, allowing for directional flow control and bypassing multiple channels. They are used when more complex flow control is needed.

Trunnion Ball Valve: A trunnion ball valve has a ball that is supported by bearings, allowing for larger sizes and higher-pressure applications.

Uses of Ball Valves

Ball valves are widely used across different industries due to their efficiency and reliability. Some of the key applications include:

Oil and Gas: Ball valves are essential in oil and gas systems for controlling the flow of crude oil, natural gas, and other fluids. Their ability to withstand high pressures and temperatures makes them ideal for this industry.

Water Treatment: In water treatment plants, ball valves are used to control the flow of water and chemicals. They are often found in filtration systems, distribution lines, and pumping stations.

Chemical Processing: Chemical plants use ball valves to manage the flow of various chemicals, ensuring safe and controlled operations. The tight seal offered by ball valves minimizes leaks and contamination.

HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, ball valves regulate the flow of fluids used for heating and cooling purposes.

Food and Beverage: In the food and beverage industry, ball valves ensure the smooth flow of ingredients, liquids, and gases, as well as maintain hygienic conditions.

Pharmaceuticals: Ball valves are also critical in the pharmaceutical industry, where cleanliness and precise flow control are required for producing medicines and vaccines.

Why Choose Ball Valves?

There are several reasons why ball valves are favored in various industries:

Durability: Ball valves are highly durable and can withstand harsh operating conditions, such as extreme temperatures and high pressures.

Leak-Proof Performance: Ball valves are designed to provide a tight seal, preventing leaks even in demanding applications.

Ease of Operation: With a simple 90-degree turn, ball valves are easy to operate and provide quick response times.

Versatility: They can be used for a wide range of applications, from small-scale systems to large industrial plants.

Low Maintenance: Due to their robust design and minimal moving parts, ball valves require little maintenance compared to other types of valves.

India has become a significant player in the global valve manufacturing industry, with many reputable ball valve manufacturers producing high-quality valves. A ball valve manufacturer in India is equipped with advanced technology and expertise to meet the growing demand for industrial valves in various sectors.

These manufacturers use state-of-the-art materials and rigorous quality control processes to ensure that their products meet international standards. As a result, India's ball valve manufacturers are well-positioned to cater to both domestic and international markets, offering products that are durable, reliable, and cost-effective.

Conclusion